StoreOpt

Innovative system for optimization and simulation of logistical operations in a pharmaceutical warehouse

StoreOpt will help you organize and operate your pharmaceutical warehouse in the most optimal and efficient way!

There are many expectations that must be met when building a new or operating an existing warehouse. There are fundamental questions, such as:

-

How many storage units should be created?

-

What types of storage units are needed?

If the product range is known, these questions are easy to answer, but then the finer steps come into play:

-

Where should each product be placed?

-

How many pickers should be hired?

-

Based on the present turnover of the warehouse, what will be the picking time?

StoreOpt helps you answer these kinds of questions!

Let us look at an example

We have a pharmaceutical warehouse.

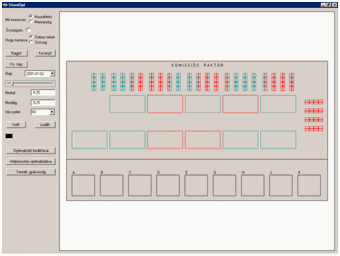

We have prepared a mock-up of the warehouse based on its blueprint (pickers are shown in the bottom row).

We can model its functioning based on either existing or designed turnover data.

Up until now, we have been modelling a layout proposed by the Client but StoreOpt will help us setting up the warehouse optimally.

Optimization criteria

Critical mass

A critical mass can be defined, and any goods exceeding this mass may only be placed on lower shelves.

Pickers

We can imagine the picking process as a conveyor belt, where the weakest link, i.e., the weakest picker determines the speed of the picking process. Provided that picking along individual sectors is not uniform, the rest of the sectors will experience downtime. Since the performance of the pickers is not identical, it is not enough to have identical picking tasks in the given sectors, because the weaker picker „slows down” the better pickers. The best course of action is to create picker groups and assign workers accordingly.

Storage space

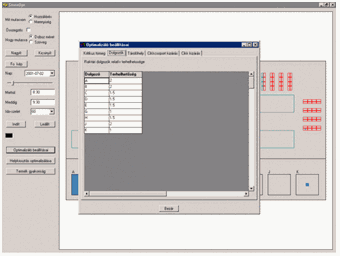

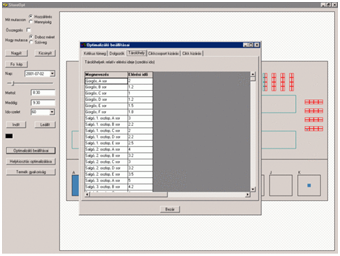

When optimizing, the goal is to reach the lowest possible cost. The picking time for storage units depends on their height, their type and their distance from the picking route. For this reason, storage unit types receive a multiplier representing the amount by which the picking cost for 1 item from the given storage unit is higher compared to the easiest storage unit to pick.

Exclusions

-

We may wish to avoid placing certain products or product groups next to one another.

-

Perhaps we wish to organize our entire warehouse with separate product groups, and only optimize inside these.

-

There may be a requirement for products with similar names not to be placed next to each other, e.g., items with the same first 4 (perhaps more or less) characters in their names.

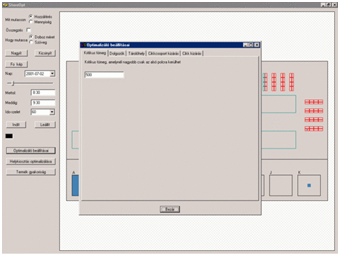

The system provides the possibility to set these exclusions.

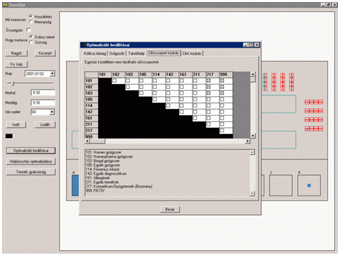

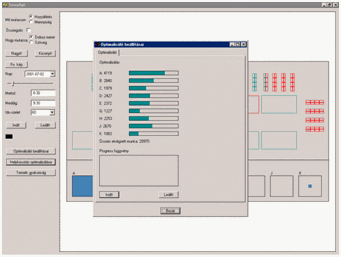

Optimization rundown

After filling out the optimization criteria, the

system attempts to create a warehouse layout where the load placed on each

section is made uniform according to the abilities of the pickers, and within

this, picking has the lowest possible cost.

Before optimization

After optimization

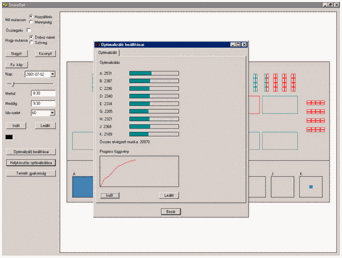

Optimization in practice

One also has to adapt to changes in the marketplace – e.g., new products arrive, turnover increases for existing items or they are phased out of the product range – while the layout of the warehouse remains unchanged. Under the effects of these external factors, the initially optimal warehouse should (could) be modified in a few months. A choice of two methods is available to us:

-

I can optimize the warehouse periodically (e.g., twice a year) according to the new state of the market.

-

I maintain the warehouse at an optimal level continuously. This means that the optimization algorithm can be told how many products it can move. E.g., I set the capacity to move 20 products each Friday, and at this time, the system looks for the 20 products whose relocation would result in the greatest cost savings.

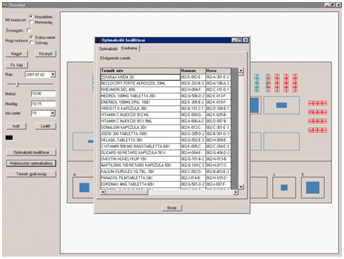

Statistics

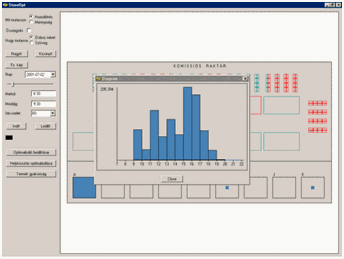

The system prepares a picking chart of all pickers, sections and storage units by clicking the right mouse button.

The warehouse in the example is an actual pharmaceutical warehouse in Hungary, and the optimization criteria in the example apply to it. The system is of course capable of optimizing warehouses with a different range of products, and it can take into account the special optimization criteria that may arise there as well.

We know well that there are no two warehouses alike!

StoreOpt can be purchased as a standalone product, but it can also be a part of the services offered by us.